Buckles are available in 2 versions:

- Galavnized Buckles for PP, PET and Hotmelt strapping

- Sherardized Buckles for Composite and Woven strapping

In the market there are also buckles from blank (rust) and blackened steel wire offered as a cheap alternative to sherardizing.

However, this has no effect at all on the quality of the buckle.

Sherardized buckles are meant for heavier loads.

During the sherardization process, the buckle(diffusion galvanizing) is the buckle heated to 350-500 °C, with zinc powder in combination with fine sand joint with the surface of the buckle. This creates a high-quality, rougher surface and higher tensile strengths are achieved.

| Type | Article Nº |

Inches |

mm |

Wire Ø |

Pcs/Box |

Pcs/Pallet |

| BF4-3.3 | 1305812S | 4/8 |

13 |

3.3 |

1000 |

112,000 |

| BF5-3.5 | 1305803S | 5/8 |

16 |

3.5 |

1000 |

80,000 |

| BF6-4.0 | 1305813S | 3/4 |

19 |

4.0 |

1000 |

60,000 |

| BF8-5.0 | 1305814S | 1 |

25 |

5.0 |

400 |

19,200 |

| BF8-6.0 HD | 1305926S | 1 |

25 |

6.0 |

400 |

19,200 |

BF10-7.0 |

1305881S | 1 1/4 |

32 |

7.0 |

250 |

12,000 |

| BF12-7.0 | 1305916S |

1 1/2 |

38 |

7.0 |

200 |

9,600 |

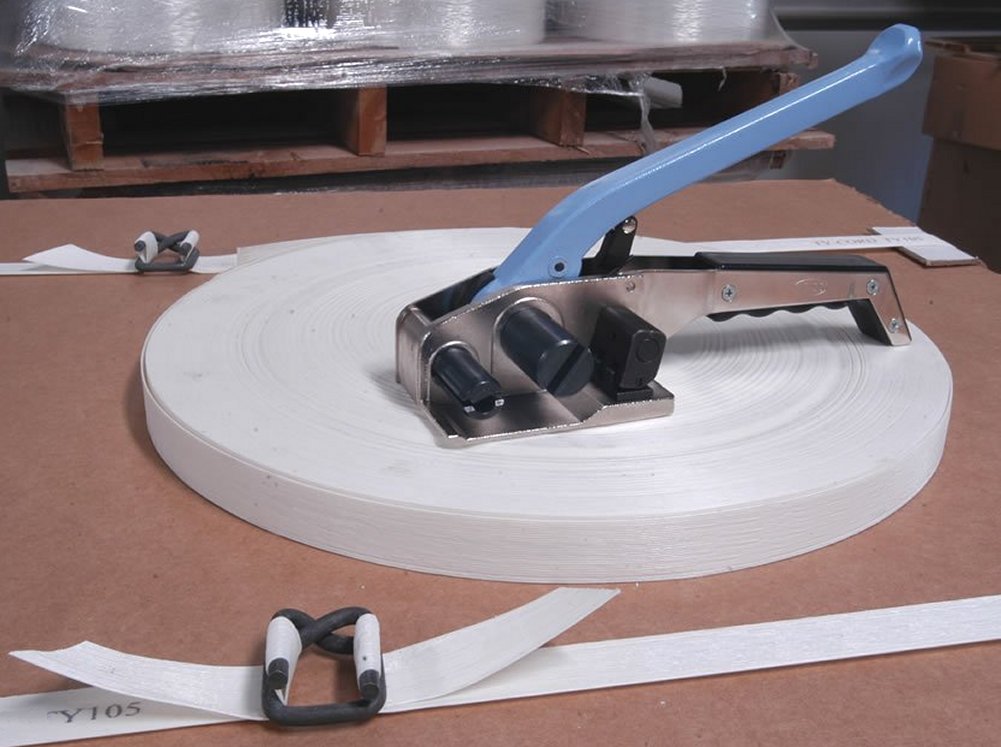

SUITABLE FOR STRAPPING TYPE

Glued Polyester (Hotmelt)

Co-extruded Polyester (Composit)

Woven Polyester

Woven Polypropylene

RELATION TENSILE STRENGTH

(any deviations are also dependent on the quality of the strapping)

| Galvanized Standard | 100% |

| Phosphated Standard | 100% |

| Galvanized Heavy Duty | 130% |

| Sherardized Standard | 140% |

| Sherardized Heavy Duty | 150% |